Between artificial intelligence, IoT and digital twin

ARGO collects and processes structural data of bridges, overpasses, viaducts and tunnels by combining advanced digitisation, artificial intelligence and innovative technologies and creating a digital inventory for advanced infrastructure life-cycle management and monitoring. With the support of a mobile app and a Digital Twin, ARGO facilitates both field and remote inspections, while the centralised database ensures optimal data and process management.

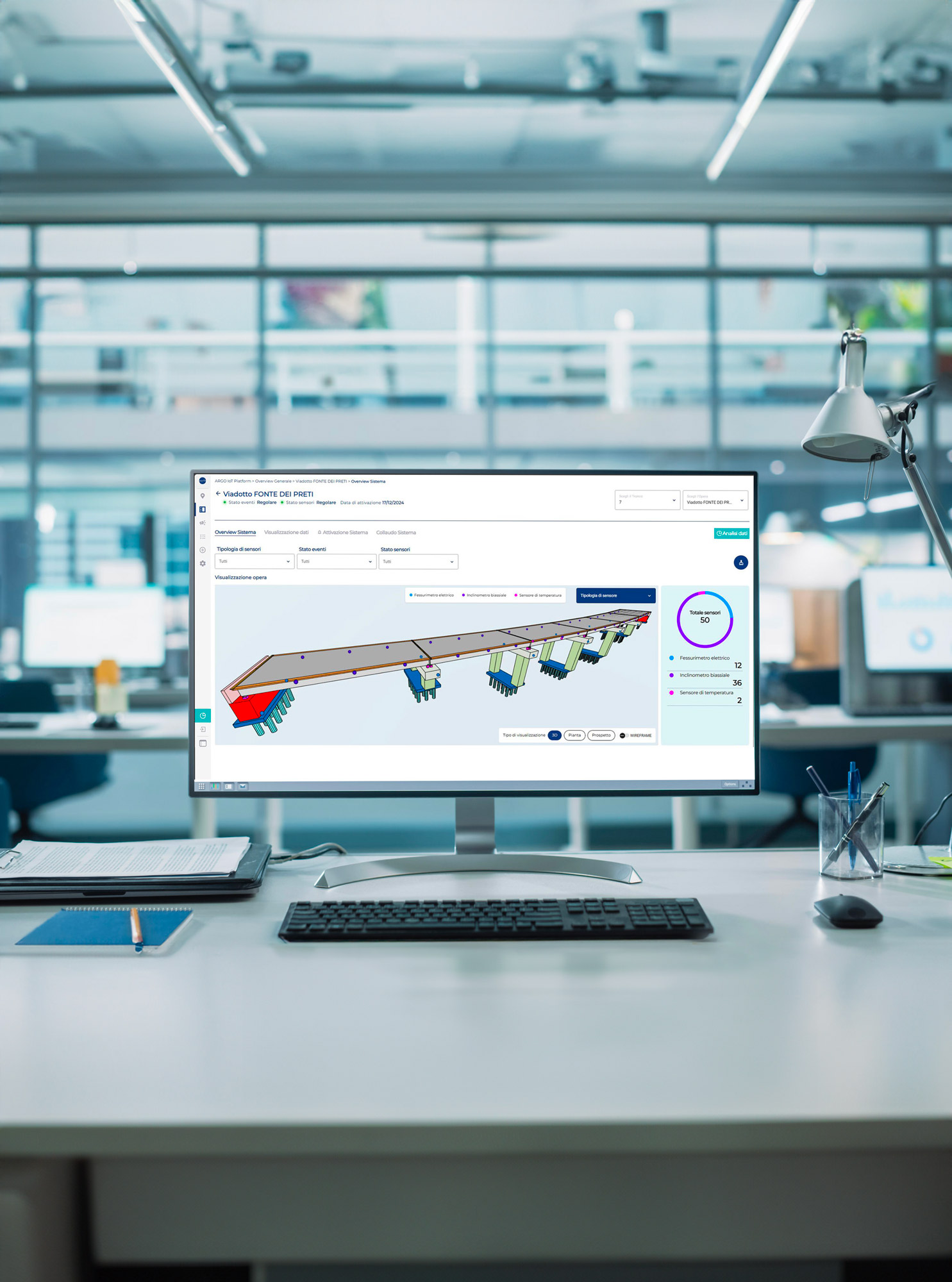

The ARGO platform can both monitor bridges, viaducts and overpasses, as well as tunnels, and can integrate data from IoT sensors for continuous and accurate monitoring of assets.

The figures of the ARGO PLATFORM

ARGO bridges, viaducts and overpasses

Argo is a platform for monitoring and managing the life cycle of bridges, viaducts and overpasses. An advanced Asset Management tool for road and motorway infrastructure.

ARGO Tunnels

ARGO Tunnel is a web-based platform designed for the management of tunnel inspections, designed to simplify the monitoring and inspection of infrastructure assets.

ARGO IoT

The ARGO IoT platform for structural monitoring is an advanced solution that collects and integrates data from sensors in the field, designed to manage and analyse the behaviour of structures in operation.

Successful Projects

Here you can take a look at a selection of our most significant projects and find out how we have helped meet our customers’ needs innovatively and efficiently.